Reference inbreast implants

Find out

About us

SILIMED, PIONEERS IN QUALITY AND SAFETY SINCE 1978.

Silimed is one of the largest silicone breast implant manufacturers in the world, proudly operating in over 40 countries. Today Silimed are recognised globally for bringing innovation to surgeons and and well-being to patients.

Over the course of more than 45 years, Silimed has worked closely with the scientific and medical community in terms of research, scientific studies and in developing new technologies. This has made it possible to ensure the quality of its implants, adapting them to the particular needs of each patient, and becoming established as a pioneer in numerous advances in terms of quality and safety in the field of surgery.

Thus, Silimed was the first company in the world to identify each implant with a serial number, ensuring its traceability and offering increased safety for surgeons and patients.

Silimed is also the most experienced company in the world when it comes to manufacturing polyurethane-coated silicone breast implants. In 1989, it developed an innovative coating technology with polyurethane foam using the process of vulcanisation. Ever since then, Silimed continues to break ground in new technologies, clinical studies and advances related to polyurethane breast implants, becoming established as a benchmark in developing solutions adapted to the particular needs of each patient.

Purpose: Empowering doctors to promote self-esteem

Connecting excellence between products

and services with safety and agility

New Silimed factory

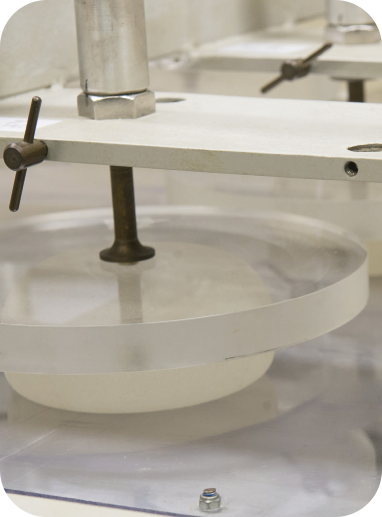

Located in Rio de Janeiro (Brazil), the Silimed factory is designed as a modern structure with state-of-the-art facilities that provide a seamless process from raw material to finished product. This enables us to comply with the highest international quality and safety standards in every Silimed breast implant.

12.000m²

of state-of-the-art

facilities

+42.000

breast implants

produced each month

Commitment to science, quality and technology

Global excellence in quality and safety

At Silimed, we prioritise quality, safety and high productivity to ensure top-quality products and services for our clients and patients.

The Silimed factory was built to attend to the global demand for breast implants, allocating continuous investment towards technology, automation and sustainability.

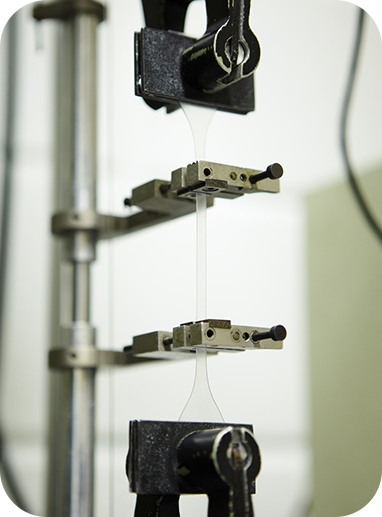

Technological excellence, quality and robotisation

- Devices with cutting-edge technology that enable us to further increase the level of monitoring and quality in our products.

- Automated manufacturing process that guarantees standardisation and an increase in productivity.

Automation and digitalisation in production

- Our comprehensive system enables us to monitor the process, ensuring full traceability, from the raw materials to the final product.

- Automation projects to mix and fill the gel, package and record the serial number.

- Digitalisation initiatives for automatic data collection of the devices and automatic reading of the serial number.